Is There Intelligent Life Out There?

One of our previous articles discussed the minerals of Star Trek, giving rise to the hope that there is extraterrestrial life out there, but the honest discussion about ET’s existence is a loaded subject.

For this article, we are going to focus on the probability of whether life exists in outer space; in other words, what are the odds that there really is intelligent life on other planets?

As difficult as it is to wrap our heads around the sun’s fusion process, which is equivalent to 100 billion atomic bombs per second, we will go one step further and try to understand the immense size of our universe, and then look at the formulas that scientists have developed to determine ET’s existence.

2023 Update on Extraterrestrial Life

It was already known that one of Saturn’s moons – Enceladus has oceans, but its Cassini spacecraft just recently found that its oceans contain the element phosphorus, which is a key chemical element in the building blocks of life.

This brings us one step closer to finding out if life exists right in our own backyard.

But what about intelligent life?

So What Are the Odds?

It is estimated that there is an average of 1 – 2 billion stars in any recorded galaxy and there are over 2 trillion galaxies out there. If 10% of each galaxy contains a solar system, that is, it contains a star that has planets revolving around it, then we can estimate that each galaxy has between 100 – 200 million solar systems, with some that may be fairly similar to ours.

If 1% of the stars in each solar system have a planet just distant enough from their sun where life could evolve, called the habitable zone or as some scientists call it, the Goldilocks Zone, we could have 1 – 2 million possible planets that could contain life.

Going further, if 1% of these planets have the right ‘ingredients’ to build intelligent life, then there is the possibility that there may exist 10,000 stars that could have planets with intelligent life in each galaxy.

Just to be more realistic, we can cut the odds even further and take 10% of this result, which would equate to the possibility of 1,000 stars with extraterrestrial life in each galaxy.

That would mean that there could be 1,000 x 2 trillion galaxies = 2,000,000,000,000,000 (2 quadrillion) planets with intelligent life. How many is that? Just take a look at this numerical comparison; thus, If we use the estimate of two trillion galaxies in the universe, that would mean ET may live on over 2 quadrillion planets in our universe.

Don’t even try to comprehend how many fusion reactions occur here every second when you include all of these stars. Fuhgeddaboudit!

What About the Scientific Formulas?

The above calculations were based on a general layman’s assumption, but have the experts given the possibility of extraterrestrial life serious thought?

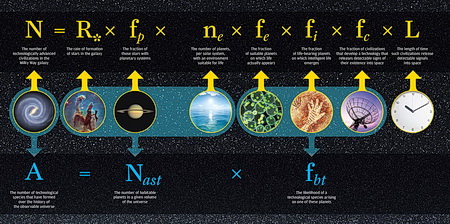

American astronomer and astrophysicist Dr. Frank Drake developed a formula that he presented at a meeting in Virginia in 1961. It is called the Drake Equation, which calculates the possibilities of life on other worlds within our own Milky Way galaxy.

We won’t go into the calculations, but in a general sense, it is based on our assumptions above but uses trigonometry to formulate a much more explicit and precise determination of ET’s existence. For you science and math connoisseurs, feel free to give it a shot below!

The terms are as follows:

N : The number of planets in the galaxy where electromagnetic emissions are detectable

R: The rate of scanability to have exoplanets with habitable Fnes revolve around them

fp : The fr those stars that have solar systems

ne : The number of planets in each solar system within the Goldilocks Zone

fl :r of planets on where life may exist

fi : The number of planets where intelligent life may exist

fc : The number of planets that have civilizations with a technology where we can detect their signals

L : The length of time that these civilizations have produced these signals

What About the UFO Sightings?

Now we come to the discussion of UFOs. If life does indeed exist, are they here or not?

Where are the Pictures?

Dr. Neil deGrasse Tyson, astrophysicist and Director of the NYC Hayden Planetarium at the Rose Center for Earth and Space had an interesting thought.

He said with all the cell phones that people have these days (which account for hundreds of millions), not one person has come forward with a clear picture of a UFO, alluding to the assumption that if there is life in outer space, they most likely have not reached us.

We are sure Dr. Tyson believes that intelligent life does exist, but he is being realistic in suggesting that ET still has to come here before he calls home.

What About Worm Holes?

Dr. Tyson’s view is the opinion of one expert and his statement is by no means conclusive. With that said, Dr. Tyson welcomes the opinions of other experts in the field, such as his colleague theoretical physicist and CUNY Professor Dr. Michio Kaku, who advances to theories beyond current reality and states that aliens could be here by way of quantum computing. (To see the complete discussion of Dr. Tyson and Dr. Kaku, check out our article on quantum computing).

The Quantum Link

We earthlings are only at the fetal stages of quantum computing, but Dr. Kaku suggests that it’s quite possible that extraterrestrial life has already harnessed quantum computing and in so doing, they have been able to obtain the answer to many questions that have baffled humans for mellimena. One such question would be is – how did the big bang happen?

Moreover, if they are able to tackle that question, there is no doubt that they also have been able to determine how a wormhole operates. A wormhole is a phonenoma that allows one to travel from one end of the galaxy to the other or event from one galaxy to another in a matter of minutes.

If this is the case, then perhaps ET is already here and with their advanced capabilities, they could easily cloak themselves from the vision of us Earthlings and if Dr. Kaku’s theories are correct, maybe, just maybe the suggestions of aliens in Men in Black are right!

Conclusion

It is mostly a unanimous decision by scientists that extraterrestrial life does exist and there is agreement that there also is intelligent life out there somewhere, so the question is are they here on Earth or not? And that is where there are still open discussions.

But regardless if they are here, would they look like us? If not what would they look like? Another interesting dilemma to consider!