What is Concrete?

Ever notice that just about every building has a concrete foundation? There is a very good reason for this and it is not about aesthetics. Concrete has enormous compressive strength, meaning that it is an excellent material for holding up the weight that is above it.

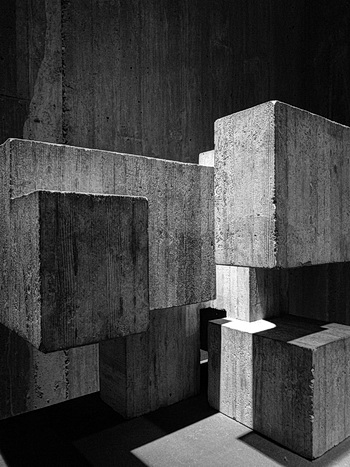

Concrete is not just used for foundations, but also for columns, and beams. slabs and just about anything where there is a load-bearing issue. Load bearing means an element that supports the weight above it. The amount of weight that the load-bearing element would support would depend upon how many concrete columns (or other concrete supporting materials) are available to support the whole load.

For example, a 30-story building has 10 supporting columns on the ground. That would mean that the weight is evenly distributed across each of the 10 columns or mathematically speaking, each concrete column would support 0.333 (10/30) of the load (building).

Another probably more identifiable example is the load-bearing walls in a house. If you live in a house, you have probably become aware of where your load-bearing walls are. These are the walls that actually hold up the house; however, for frame houses, concrete is not the usual load-bearing material, but heavy wood or steel instead.

In short, concrete is an excellent source for withstanding the heavy forces that are above it or more specifically, as an excellent compression material.

Did you know that concrete also gains more strength as it ages? With that said, let’s take a look at just what this compressive material is actually made of.

What is Concrete Made Out of?

Concrete is a mixture of air, water, sand, and gravel and the percentages of these elements are usually 20% air and water, 30% sand called fine aggregates, and 40% gravel, with 10% being cement; that is, 10% being the ‘glue’ that keeps all those other materials together. Remember, from our article on cement, it is just the binding material for the assembly of concrete. When the cement is mixed with water, it is called paste.

This proportion is called the 10-20-30-40 Rule; however, the exact percentages of the materials can vary depending on the combination of the concrete mixture, including the type of cement and other factors that we will explain in this article.

How are the Proportion of Materials that Form Concrete Determined?

So we know that concrete is a mixture of paste and aggregates and sometimes rocks. The paste coats each of the aggregates and as it hardens (the process is called hydration), concrete is born until it becomes a rock-solid mass, capable of withstanding a load much heavier than itself, but if the proportion of water and paste is not correct, this rock-solid mass can deteriorate causing unwanted and potentially dangerous consequences.

The trick is to carefully proportion the mix of the ingredients and much of it depends on the ratio of water to cement and this ratio is calculated by the weight of the water divided by the weight of the cement. A low water-content ratio yields high-quality concrete, so it is best to lower the ratio as much as possible without sacrificing the integrity of the concrete.

If the ratio results where there is too much water in the mixture, the aggregates become thinned out, resulting in weakening the concrete and we can figure out what that would mean.

Conversely, If there is not enough water in the mix, the water will evaporate too fast, compromising the integrity of the concrete and resulting in it being weak as well.

What is the Strongest Concrete Mixture Ratio?

1:3:5 which is cement and aggregates (in this case, the aggregate is broken into sand (3) and gravel (5), and this is considered the ratio that would create the strongest concrete.

What Happens if the Wrong Mixture of Concrete is Used?

If the ratio of the concrete mix is not done correctly, there can be a variety of problems, such as compromising its integrity which can lead to disastrous results.

Cracking

Excessive water content, inadequate curing, or incorrect proportions of cement, aggregates, or water can contribute to cracking. These cracks can compromise the durability of the building and allow moisture penetration, leading to further deterioration over time.

Reduced Strength

Concrete strength is a critical factor in ensuring the structural integrity of buildings. If the concrete mix has an incorrect ratio of the required additives, it may not achieve the strength needed to maintain its load. This can compromise the load-bearing capacity of the structure and lead to collapse or deformation under normal loads.

Ultimately, using an improper concrete mixture poses safety risks to occupants and users of the building. Structural failures or deterioration can lead to accidents, injuries, and even loss of life in severe cases.

Champlain Towers Building Collapse

One recent incident occurred in Surfside, Florida where the Champlain Towers collapsed on June 24, 2021, and 98 people lost their lives.

The investigation is still ongoing but they have found structural defects in the design of the pool, as well as compromised integrity of the columns that supported the building.

How Much Time Is Allocated Before the Finished Concrete Is Used at the Construction Site?

There is a limit to how long the concrete can be poured after it is mixed. In the US, the limit is 60 minutes from the time the water mixes with the cement to the time of delivery to the construction site.

A safe time frame is up to 90 minutes, then the integrity of the concrete will start to deteriorate. That is why we see concrete mixers right at the construction site as no time is lost between the mixture and the pouring.

What About Reinforced Concrete?

As the name applies, when steel (usually using steel bars, called rebars) is placed inside the slab where the concrete is going to be poured, it reinforces the strength of the concrete.

How Does Rebar Reinforce Concrete?

We have been discussing compression strength; that is, how strong the material is when a heavy load is placed on it, but we haven’t discussed tensile strength, which is the opposite of compression.

Tensile strength represents the strength a material can endure when a force tries to pull or stretch it out. The reason why compression is so important when using concrete is that that is its main purpose – to hold up heavy loads, but concrete does have a limit on how much pull can be leveled on it as well, and there are situations where the tensile strength of concrete is put to the test. The weather being one factor, but there are more.

Enter Steel

By integrating the rebars inside the concrete, the concern about stretching the concrete is greatly minimized. The combination of concrete and its accompanying reinforcing steel bars successfully manages these situations, because of steel’s high tensile strength; hence, you have a perfect storm of compressive and tensile strength in reinforced concrete (RC).

What Happens if the Reinforcing Steel is Not Inside the Concrete?

Cracking of the concrete surfaces can occur, subsequently causing aesthetic issues, but if the tensile yield is really great, (e.g. a strong pull on the concrete) the situation can become unsafe, so without the steel rods to compensate for this pull, you will find cracks in the concrete or worse.

Conclusion

Concrete is a mixture of sand, water, aggregates and cement. The amount of any of these elements will determine the strength of the concrete. Timing also plays a role as the concrete must be readily mixed within 90 minutes max, but 60 minutes is the usual requirement before being poured into its foundation or another element such as a column or slab.

By placing steel bars which is a mesh of steel wires (rebar) inside the concrete, the tension issue is resolved by aiding the concrete under tension.

So the next time you are walking in a building, especially a large structure such as a skyscraper, give thanks to the materials that allow you to be there, as well being thankful to the engineers who allowed it to happen!