Overview

In the last few years, there has been a lot of buzz about the metal known as titanium. The reason is that it has quite a few properties that make it useful in everyday life.

It is strong, lightweight, and corrosion-resistant among other things. It is most popular for being used to create aircraft parts and car engine components; however, there is so much more to this metal than meets the eye.

People have used titanium for thousands of years. Only recently we have begun to understand exactly how useful this mineral can be. It was found to be extremely useful for military stealth functions, starting with the famous SR-71 reconnaissance aircraft, due to the metal’s strength and high-temperature resilience (as we will discuss below) and the fact that it is lightweight (e.g. in this case, functioning as a very strong material but light), it was perfect for this spy plane.

Let’s take a look at some interesting facts about titanium.

Properties Stronger than Steel

You might have heard that titanium is as strong as steel. While this is not entirely true, it is close enough to be significant. To begin with, strength is not a single chemical property of a material. But for simplicity, let’s treat it as one.

The tensile strength (measurement of a material’s elastic stress when a load is placed on it – how much it can withstand before starting to stretch or pull out before breaking apart) of steel is around 100 gigapascals (GPa) – the unit of measurement of tensile strength. (One pascal is equal to 1 newton of force per square meter).

The tensile strength of titanium is about 60 GPa. Therefore, steel is stronger than titanium. However, the thing to note here is that titanium’s strength is applied only at a very specific point. Let’s say that you have a piece of metal that has a high tensile strength across its entire surface. This does not make it stronger than a piece of metal with a lower tensile strength applied at a specific point.

Chemical Properties of Titanium

Titanium has a lot of unique properties that make it special. It has a very high melting point (more than 3,000 degrees Fahrenheit). Because titanium resists oxidation at high temperatures, it is often used in high-temperature applications.

Oxidation is the loss of electrons, resulting in the titanium atoms becoming vulnerable to combining with other atoms; subsequently changing their properties and compromising the material.

A perfect example of using titanium for its resistance to oxidization at high temperatures is that it makes an excellent material for the SR-71 since this plane could fly at Mach 2.5, which is close to 2,000 miles per hour. This metal is also corrosion-resistant. This means that titanium is very useful when exposed to water or air.

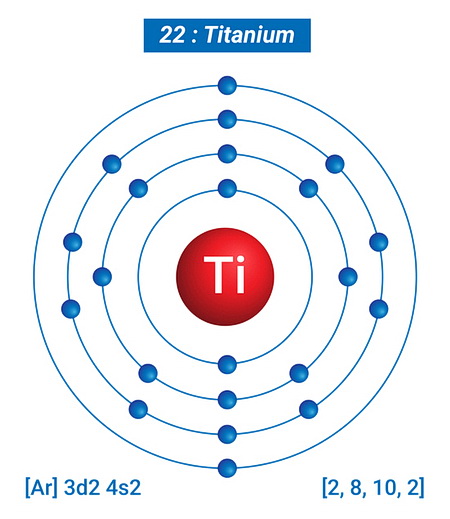

Titanium has an atomic number of 22 and an atomic weight of 47.867, which means it has 22 protons and approximately 48 protons and neutrons, respectively.

Everyday Uses of Titanium

Titanium is being used in many different industries, and there are several everyday uses of titanium that you may not be aware of. This is because titanium is lightweight, strong, and corrosion-resistant, making it the perfect material for sports equipment.

-

- Sports equipment – If you are a sports fan, you may have seen athletes wearing titanium-containing sports accessories.

- Medical equipment – If you ever get an MRI scan, you may be inside a machine that is made of titanium. This is because titanium is very safe to use around living tissue and can be sterilized easily.

- Marine parts – If you own a boat, you may be surprised to learn that the propellers and rudders are often made of titanium. This is because it is strong, lightweight, corrosion-resistant, and does not affect water flow.

- Water and air purification – You may have seen pictures of large towers in cities. These towers are used for water purification and are often made of titanium.

- Construction – Buildings, bridges, and other infrastructure are often constructed using titanium. This is because it is highly corrosion-resistant and very strong.

- Food packaging – If you have ever eaten food that was in a pouch, there is a good chance that the pouch was made of titanium.

How is Titanium Produced?

Titanium is made through a process known as the Kroll process. – First, titanium ore is mined and then sent to a smelter where it is heated to extremely high temperatures.

The resulting molten metal is then sent through a chemical reduction process which removes oxygen and other impurities. The molten metal is then cast into ingots and then rolled into long bars. These bars are then drawn through a press that elongates them and makes them thinner. Finally, the bars are shaped into their final forms and then sent to be coated or processed further.

Problems with Manufacturing and Existing Processes

As you have read, titanium is a very versatile material that can be used in a wide variety of industries. However, there are some issues with the current methods of manufacturing this mineral that needs to be addressed.

-

- High costs – Currently, the process of producing titanium is very energy-intensive and expensive. The cost of the metal itself is also quite high, making it costly to produce certain products.

- Contamination – The process of manufacturing titanium is quite complex, and there is a risk of contamination in certain areas of the process.

- High purity requirements – Another issue with titanium is that it has very high purity requirements. This means that the resulting metal can be very impure even after the purification process.

- Difficult to produce large quantities of titanium in the quantities needed for the industries that use it.

Concluding Words

Titanium is a very versatile metal that can be used in a wide variety of industries. However, due to its high costs and difficult manufacturing process, it is often difficult to produce large quantities of titanium. With that said, titanium is used for very specific functions. This article has explored the many uses of titanium and the process behind its manufacture.